NOTICE TO THE INSTALLER OR PURCHASER

As indicated on the box, the hood should be connected and tested prior to installation; if the hood works properly at that time but a problem arises after installation, the problem is not due to the hood but to improper installation somewhere between the hood and the outside vent.

Types of malfunction:

- Noise and vibrations from the hood

- The motor makes a screeching sound and seems to be forcing

- The suction power seems to be approximately the same for all settings.

Check the vent

- The most common problem is range hood flaps that fail to open:

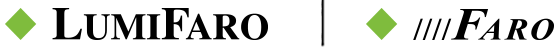

- Did you remove the protective adhesive strip on the flaps?

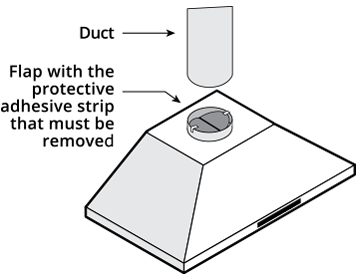

- Did you install the duct too tightly over the flaps, preventing them from opening fully?

- Never use screws to attach the duct to the hood outlet. Use duct tape instead

- To quickly check whether the valves are operating properly, run the hood for 30 second then turn it off. After 2 or 3 seconds, you should hear the two flaps close one after the other.

- liste

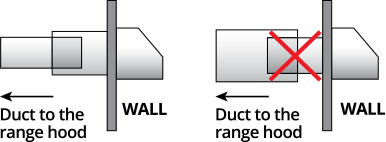

- The duct connecting the hood to the outside should be the same diameter as the hood’s outlet (typically 6 inches) and be free of obstacles.

- Caution! Never put an angled duct right at the outlet of the hood.

- liste

- liste

- liste

- Use the following vents

• SOFFIT VENTS • WALL VENTS

CAUTION! DO NOT USE THESE VENTS

• HEATING SYSTEM GRILLE • ROUND VENT (for bathroom fans)

- If the hood is mounted on a glass-ceramic wall, it may seem noisy at the lowest setting. This can be fixed by installing a piece of 1/2-inch foam rubber between the hood and the wall.

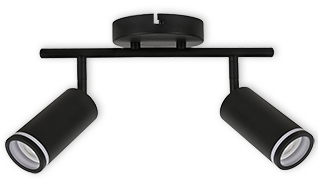

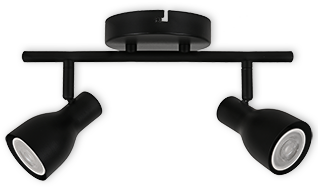

Track

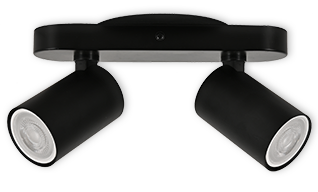

Track  CK-22104-2

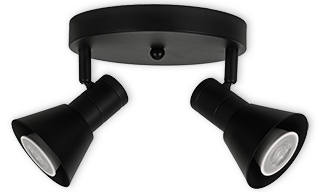

CK-22104-2 CK-22104-3

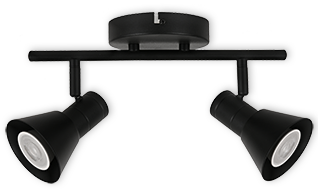

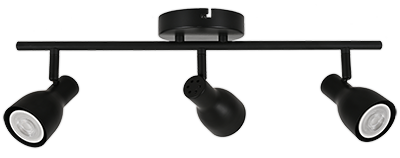

CK-22104-3 CK-22104-4-square

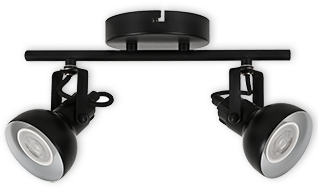

CK-22104-4-square TK-22104-2

TK-22104-2 TK-22104-3

TK-22104-3 TK-22104-4

TK-22104-4 Series 190

Series 190 CK-15190-2

CK-15190-2 CK-15190-3

CK-15190-3 CK-15190-4-square

CK-15190-4-square TK-15190-2

TK-15190-2 TK-15190-3

TK-15190-3 TK-15190-4

TK-15190-4 Series 215

Series 215 CK-161215-2

CK-161215-2 CK-161215-3

CK-161215-3 CK-161215-4-square

CK-161215-4-square TK-161215-2

TK-161215-2 TK-161215-3

TK-161215-3 TK-161215-4

TK-161215-4 Series 302

Series 302 CK-220302-2

CK-220302-2 CK-220302-3

CK-220302-3 CK-220302-4-square

CK-220302-4-square TK-220302-2

TK-220302-2 TK-220302-3

TK-220302-3 TK-220302-4

TK-220302-4 Series 304

Series 304 CK-220304-2

CK-220304-2 CK-220304-3

CK-220304-3 CK-220304-4-square

CK-220304-4-square TK-220304-2

TK-220304-2 TK-220304-3

TK-220304-3 TK-220304-4

TK-220304-4 Recessed

Recessed  Slim LED

Slim LED  Trims

Trims Housings

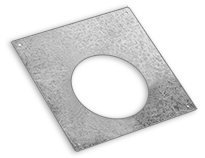

Housings Plaster frames

Plaster frames Vapor barrier

Vapor barrier LED

LED LED A19

LED A19 LED AT19

LED AT19 LED BR-30

LED BR-30 LED CTC

LED CTC LED FILA

LED FILA FILA19WH 8W

FILA19WH 8W FILA19WH 10W

FILA19WH 10W LED G9

LED G9 LED G25

LED G25 GT25 5W

GT25 5W LED GU-10

LED GU-10 GU-10 7W

GU-10 7W LED PAR-20

LED PAR-20 PAR-20-L 7W

PAR-20-L 7W LED PAR-30

LED PAR-30 PAR-30LN 11W-13W

PAR-30LN 11W-13W PAR-30LNL 11W

PAR-30LNL 11W LED PAR-38

LED PAR-38 LED ST19

LED ST19 LED CEILING

LED CEILING CLD-Ceiling lights

CLD-Ceiling lights CLD-206-30K

CLD-206-30K CLD-211-3CCT

CLD-211-3CCT CLD-214-30K

CLD-214-30K CHL-Flat Flush

CHL-Flat Flush  CHL5R-30K/40K

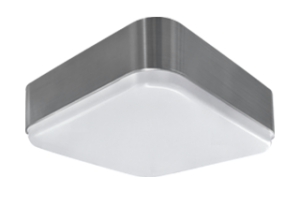

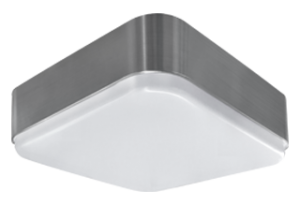

CHL5R-30K/40K CHL5R-MS-30K

CHL5R-MS-30K CHL5R-MSD-30K

CHL5R-MSD-30K CHL5S-30K/40K

CHL5S-30K/40K CHL7R-30K/40K

CHL7R-30K/40K CHL11RP-30K/40K

CHL11RP-30K/40K CLS-SQUARE

CLS-SQUARE  CLS-211-30K

CLS-211-30K CLS-214-30K

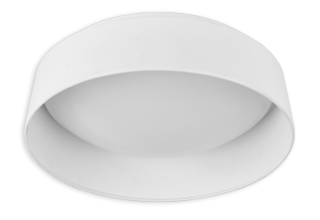

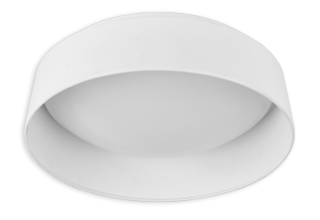

CLS-214-30K CLC-Round

CLC-Round  CLC-211-30K

CLC-211-30K CLC-211-3CCT

CLC-211-3CCT CLC-214-30K

CLC-214-30K CLC-07

CLC-07 CLC-2011

CLC-2011 CLC-2015

CLC-2015 CL23P-ROUND

CL23P-ROUND CL23P12

CL23P12 CL23P15

CL23P15 CL-EPT Ceiling lights

CL-EPT Ceiling lights CL-EPT9

CL-EPT9 CL-EPT16

CL-EPT16 CL-L11

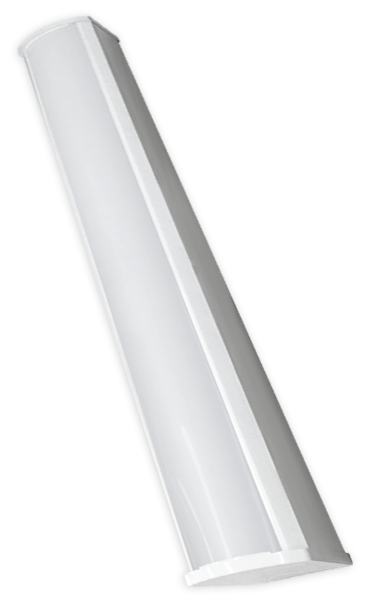

CL-L11 CLW-Shop light bar

CLW-Shop light bar CLW-240

CLW-240 CLW-480

CLW-480 Cabinet

Cabinet  Led

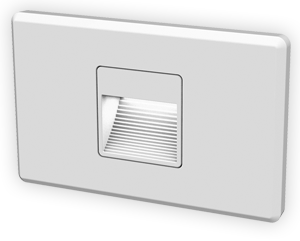

Led  Step

Step SL-250

SL-250 Step

Step SL-44R

SL-44R SL-44S

SL-44S Transformers

Transformers SL-DR12

SL-DR12 Outdoor

Outdoor LWL-13W-30K and

LWL-13W-30K and  LWL-D9W-30K

LWL-D9W-30K LWL-UD9W-30K

LWL-UD9W-30K LWL-UD5-15W-40K

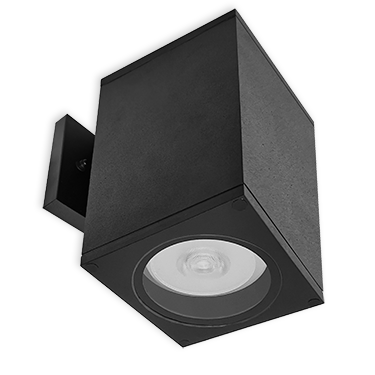

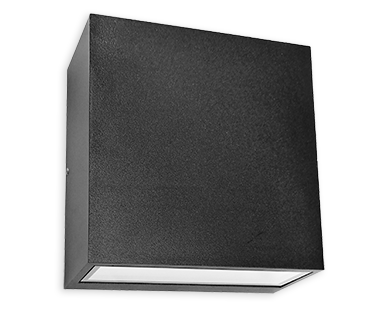

LWL-UD5-15W-40K LWL-DR30 and

LWL-DR30 and  LWL-UDR30 and

LWL-UDR30 and  LWL-UD5R38

LWL-UD5R38 LWL-DS30 and

LWL-DS30 and  LWL-UDS30 and

LWL-UDS30 and  LWL-PD-9W

LWL-PD-9W LWL-523P

LWL-523P Outdoor

Outdoor  Chimes

Chimes DC-B01-bk-wh

DC-B01-bk-wh DC-BL01-bk-wh

DC-BL01-bk-wh DC-6203-bk-wh

DC-6203-bk-wh Range

Range Wall-mount

Wall-mount Rainbow-pro

Rainbow-pro Rainbow-pro

Rainbow-pro Rainbow

Rainbow Rainbow

Rainbow Slim

Slim  Slim

Slim  Slim

Slim  Islands

Islands Slim Island

Slim Island  Under-cabinet

Under-cabinet Baby-Pro

Baby-Pro Baby-Pro I

Baby-Pro I Baby-Pro II

Baby-Pro II Built-in

Built-in Elite

Elite Elite-Pro

Elite-Pro  Elite-Pro

Elite-Pro  Information

Information